A Small Investment

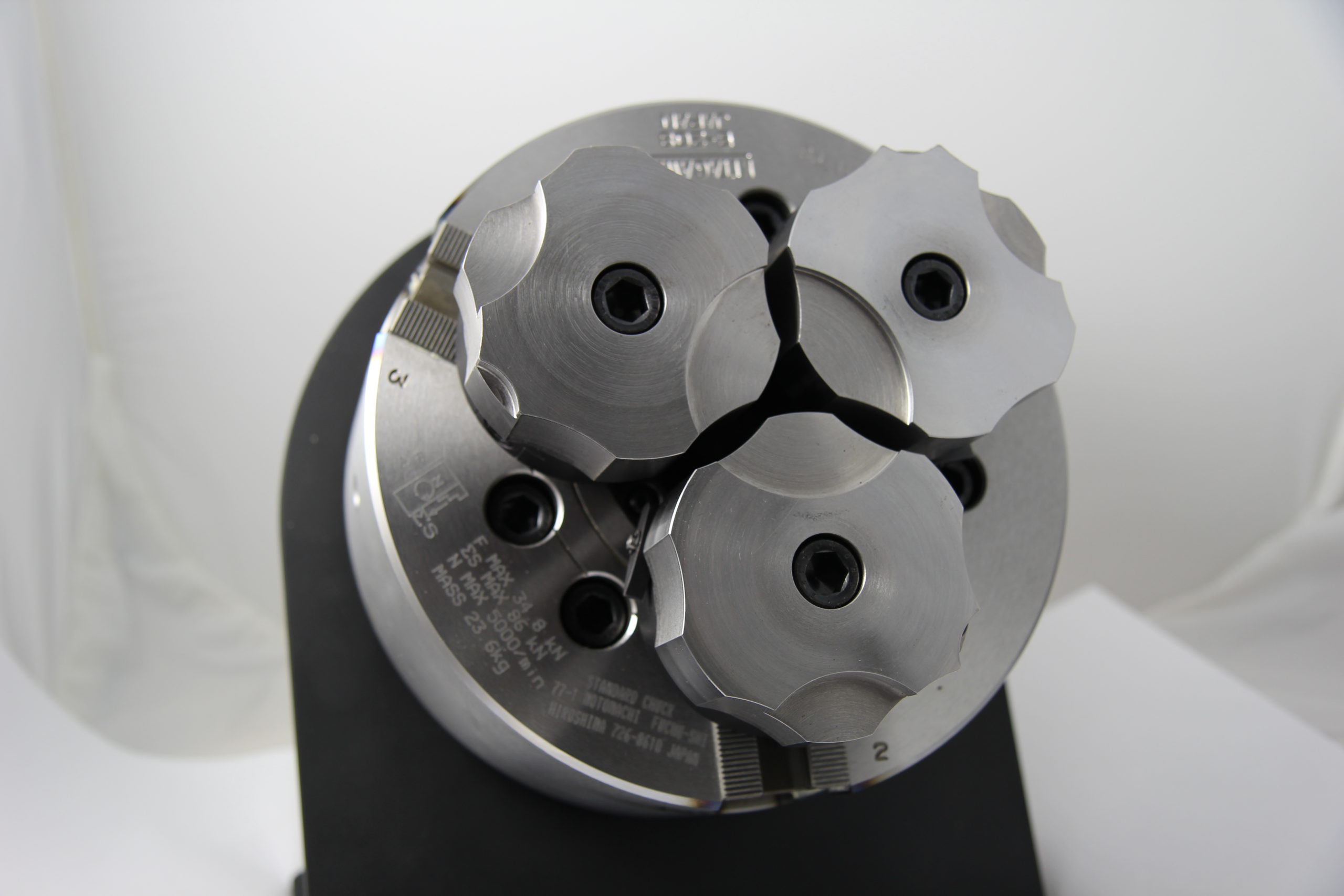

6 clamaping positions for inside and outside clamping. .

Soft and Hard jaws

For bars or blanks, for primary and sub-spindle, for soft or hard clamping.

More than "Quick Change" Jaws

Work with multiple diameters without changing top jaws.

100 % Circumference

Less clamping marks, measuring time, deformation and a grinding.

Save Set-Up Time by 95 %.

Cover 50 mm diameter within one minute. Cover 20-200 mm within 2 minutes.

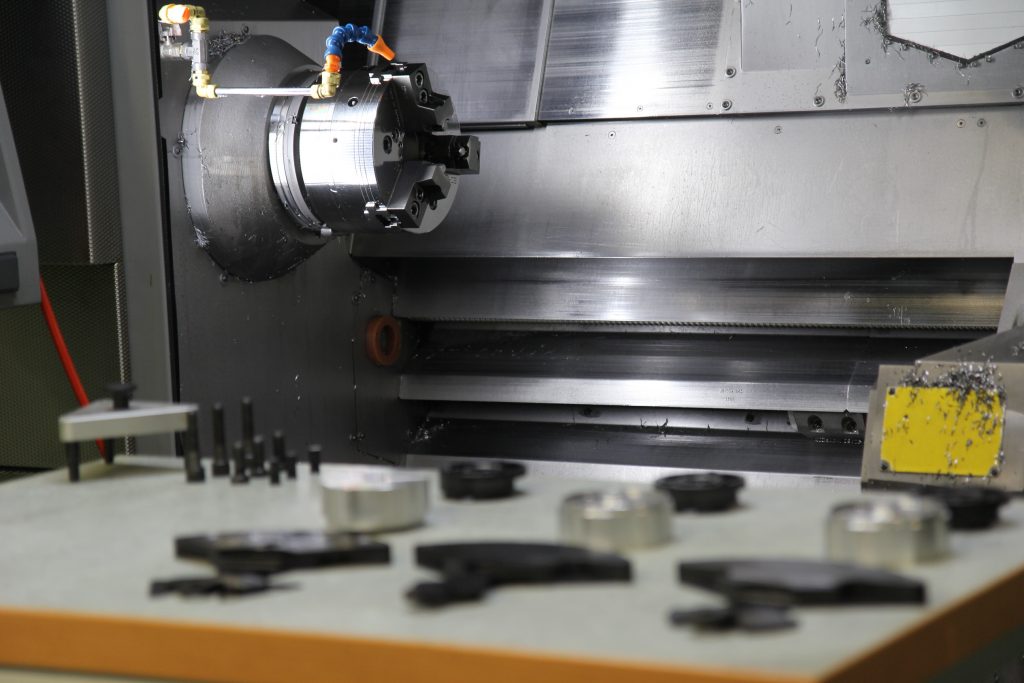

Use your own Chuck

Supporting jaw for your standard lathe chucks. For chuck sizes 8-12 inch.

Great repetability

RINDEX repeats at 20 µm

RINDEX®: Rotate & Index

Indexing means moving into a new position quickly and easily but also precisely

Wikipedia: Indexing (motion)

Shapes and sizes

Choose your type of jaws after job requirements. Make a request for special sizes, shapes and materials.

- For your standard 3 jaw chuck

- For chuck sizes 6″, 8″, 10″, 12″

- Compatible with counterweights

- Cover Ø 30-200 mm. diameter

- Cover 100% clamping surface up to 150 mm.

- 6 positions

- Robot ready

- Super quick change over time

- I.D. and O.D. clamping

- Cover Ø 0-200 mm. diameter

- Cover 100% clamping surface up to 150 mm.

- 6 positions

- I.D. and O.D. clamping

Large clamping Surface

A deep dive into Rindex

Rindex Multi Jaws is simple to use which creates values beyond quick set-up time. It’s a small investment that will pay off from the very start.

6 positions per top jaw means more work done with one set of jaws. Rindex can fit an entire job with multiple diameters on one set of top jaws. It’s easier to switch between shifts and the jaws could be keept for recurrent jobs.

When you need to change top jaws, our quick-change system makes it simple. Change size, form and material after job requirements in a minute.

Continue reading

Rindex Multi Jaws are truly revolutionary. All the benefits of quick change, large I.D. and O.D. range, 100% clamping surface, and 6 positions in one simple design.

Rindex Counterweights allow you to use large and heavy top jaws without losing clamping force. You can reduce clamping force by up to three times and still use the optimal spindle speed for your parts.

The real cost of jaws are when in use, not when purchesed.

“Smart change”- jaws decrease set-up costs by a lot. You will most likely make a profit on your very first set of jaws. This is how:

- Increase gross margin by 65%…

- By reducing setup costs by 95%…

- Cutting rework and inspection time.

Machine downtime is more costly than tooling costs

Research by Sandvik Coromant shows that a 30% saving on cutting tools results in a 1% decrease in total cost, while a 30% increase in machining time increases the gross margin by 15%. For more information follow the link below.

Mounting the base jaws takes a few minutes with perfectly centered jaws every time. How? Thanks to our smart set-up tools. Once installed, you are ready for a wide range of operations. Top jaws can be changed within a minute, for example when switching from hard to soft jaws.

Stop running back and forth replacing jaws within and between jobs. Case studies show that finding and setting up tooling is a major source of both downtime and frustration. Rindex Jaws will be appreciated by your staff and will improve their productivity.

By having multiple identical clamping surfaces on the same set of jaws, you can recover from a breakdown within minutes instead of losing 30-60 minutes.

Store sets – for recurrent jobs

Since one set of Rindex Jaws can cover an entire job, you can make small batches with a profit.

Save stock space by replacing your existing jaw stock with just a few sets of Rindex Jaws.

- Shorter delivery time

- Partial delivery

- No clamping marks

- Do the same work with 3-6 times fewer jaws

- Less material waste due to the large clamping surface

- Reduce waste with frequent quality checks, thanks to the ability to produce short series or even part-by-part without any machine downtime

A workholding tool that is simple to use. Loosen the screw, turn top jaw, fasten screw, done. Keep for recurrent jobs.

The proper selection of workholding involves more than simply accepting the chuck that came with the machine as the solution, but manufacturing managers on the shop floor often feel that they lack the in-house resources to determine the best non-standard alternatives. ... a shop should invest the time to research the most appropriate solutions.

BILL GRAHAM, MARKETING MANAGER, KITAGAWA-NORTHTECH INC.

Catalog

View our product cataloge and extra material for inspiration here...

Rindex works for you

Our new product line – The Rindex Series – is for thin walled or sensitive parts. Increase manufacturing output (parts per minute) with excellent finish, stay well within tolerance specifications and deliver on time.

Calculate profits

See how much more parts per minute you can achieve by increased machining

Optimization made easy

Learn how to optimize cutting data by choosing correct clamping force and spindle speed.