Fastest Bar Puller On The Market

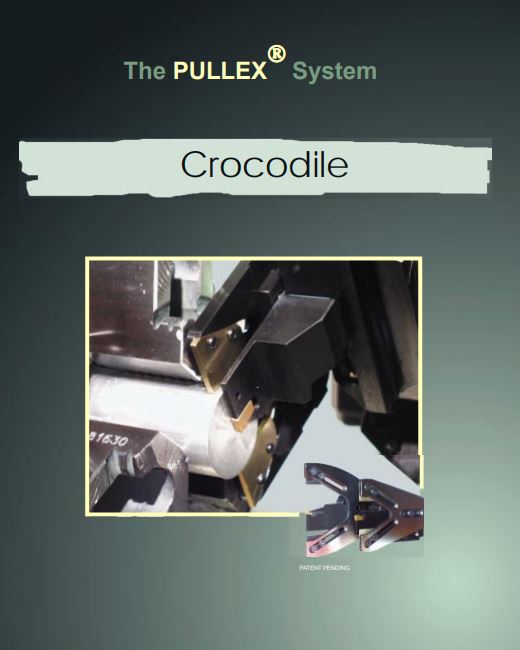

Fitted onto the Part-off tool shank, the PULLEX Crocodile pulls the bar into its new cutting position instantly as the tool’s retract for ATC.

- Fitted together with the part-off tool

- incredibly fast – clamps the bar instanteneously after cut-off

- Flexible design – can be ordered as a ready-to-run unit with tool holder or to fit with an existing toolholder

- Compact design

– Doesn’t need it’s own turret station

– Very narrow – builds out very little

– Clamps very close to the chuck jaws

- Easy to setup and use

A deep dive into Pullex

Save one day a week

|  |  |  |

| Cut-off | After cut-off the spindle is stopped | PULLEX advances a little behind the bar centre for gripping the bar | The chuck jaws are unclamped and the bar is pulled out into the new cutting position |

| Shank-application: The fixing plate is fitted between the tool holder and the upper side of the part off square tool. The frame is fitted to the fixing plate. |  |

| Blade-application: The fixing plate fits diffent sizes and brands of tool holders and is screwed on the tool holder. The frame is fitted to the fixing plate. |  |

|

How to select the right fixing plate for Pullex Crocodile

|

Pulling plates

|

| The pulling plates are pushed within their grooves (in the direction of the arrows) into the desired diameter within the Frame’s range of 30 mm. Adjust the pulling plates to a diameter of 0,1 mm to 0,2 mm less than the bar diameter. The pulling plates are hardened and profile-ground for best performance. |

| After cut-off, the spindle is stopped and PULLEX advances a little (see “A”) behind the bar centre for gripping the bar. |

Gripping capacity 1-60 mM

FAQ – Frequently Asked Questions

Below you’ll find the most common asked questions about Pullex. If you have any questions about Pullex or our other products please contact us.

Question: Can I use my own part-off tool together with Pullex Crocodile?

Answer: Yes. Iscar need not to to be prepared with M6 screw holes in the holder. Other manufacturers do.

Question: Can I use both left- and right hand tools?

Answer: Yes, the same Pullex Crocodile can be used both for left and right hand tools.

Question: How do I adjust the pulling plates?

Answer: It’s easy. You just adjust adjust the Pulling Plates 0.1 to 0.2 mm less that the bar diameter.

One way to adjust the pulling plates, when the Pullex Crocodile is mounted in the the machine is to use the following method:

The adjustment of pulling plates is simplified by turning a diameter of 0.1 mm to 0.2 mm less than the bar diameter. Then, the pulling plates are pushed against the turned diameter and locked in this position. This method is quick, accurate and eliminates errors originating from the turret and/or tool holder.

- Turn a diameter of 0.1 to 0.2 mm less than the bar diameter.

- Push the Pulling plates against the turned diameter to be locked in this position.

- The clamping force achieved by the Pulling plates entering the bar is then amplified by the somewhat sagging bar at chuck unclamp, thus securing safe operation.

Question: Does Pullex works with a spring?

Answer: No, Pullex doesn’t use any spring which can tear out