Centrifugal force compensation - soft clamping

Stay well within tolerance requirements

Cut delivery time by reducing grinding, rework and measurement time

Use large and heavy jaws without RPM restrictions

Your problem: Manufacturing sensitive or thin walled parts to fine tolerances without clamping marks.

Our solution: Use large enclosing soft jaws and add couterweights for soft clamping.

Your problem: Choosing between high Metal Removal Rate (MMR) and cutting tool life.

Our solution: Choose long lasting “quick change” cutting inserts and couterweights for high speed machining.

Read more under “Speeds and Feeds”

Your problem: Choosing between low clamping force and high RPM.

Our solution: Use low clamping force and add counterweights for high speed machining.

On this page

Summary & video

- Short summary of opportunities

- Showcase Video

Models

- Choose chuck size

- Choose model

Product advantages

- Quality improvements

- Profit improvements

Goodbye Deformations

Manufacture thin walled, delicate parts without clamping marks. Increase machining time with less quality checks, rework and grinding.

Speed up – for quick results

Cut cycle time in half when manufacture fine surfaces regardless of size and weight of jaws.

Optimize.

Increase metal removal rate, surface finish and/or tool life through with optimal kN / RPM ratio.

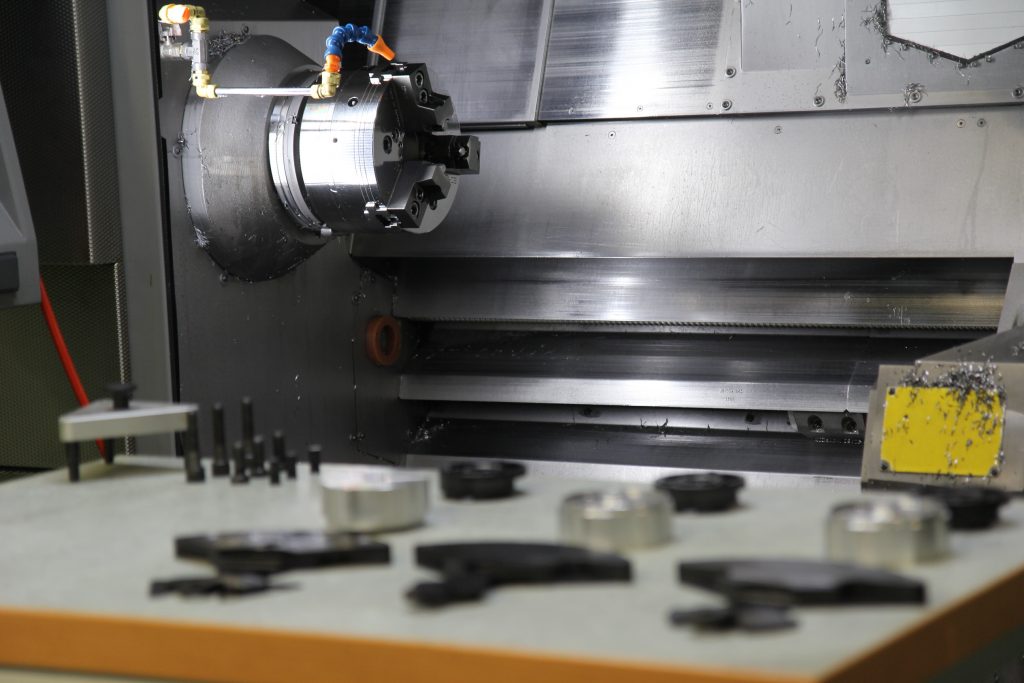

Mount onto your existing chuck

Quick installation onto primary or sub-spindle. An easier, more dynamic and cheaper alternative to centrifugal compensating chucks.

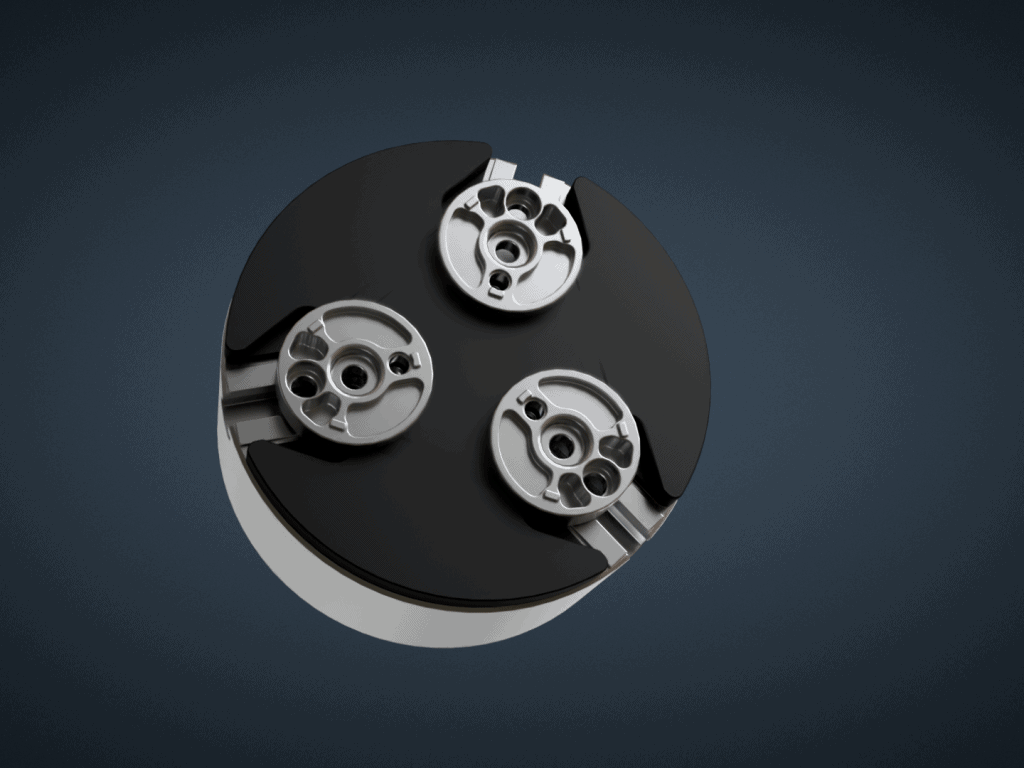

Rindex® Counterweights

Two models available to you

Our Revolution model allows you to use Rindex Multi Jaws – the smart change solution. Save time when the machine is in use or at standstill amounting up to 300 % higher gross margin.

Our Optimizer model you use extra weights to compensate for any typ of top jaws as well as achieve optimal clamping preassure and RPM for all operations.

Increase spindle speed for faster returns. Use Rindex quick with Rindex multi-jaws to save time when the machine is in use or at standstill.

- Centrifugal force compensation

- Maximal spindle speed optional

- Compatible with Rindex quick change Multi-Jaws

- Set and forget base jaws

- Compatible with standard chucks

- Different sizes and weights available

- Fully seald chuck center

Included: Case, setup Tripod, One set of base jaws, t-nuts

- Centrifugal force compensation

- Maximal spindle speed optional

- Compatible with Rindex quick change Multi-Jaws

- Set and forget base jaws

- Optimal clamping force optional

- For I.D clamping compensation

- Additional weights for top jaw compensation

- Compatible with standard chucks

- Different sizes and weights available

Included: Case, setup Tripod, One set of base jaws, t-nuts, centrifugal force measurement machine (loan), one set of extra weights

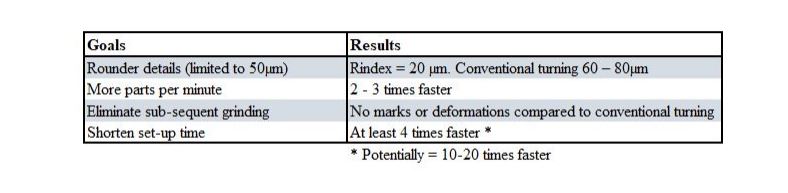

Reduce grinding, rework and measurement time

A Deep Dive Into Rindex Counterweights

Our centrifugal force compensating weights are truly revolutionary. Rindex counterweights will enhance your output quality as well as increasing your production rate.

By combining our patented counterweights and Multi Jaws, you could triple your productivity when manufacturing delicate parts where clamping forces matter.

Increased machining time means reduced costs, faster deliveries, and more competitive pricing. A clear win-win for you and your customers.

Read more…

Stay well within tolerance requirements when handling soft and/ or thin-walled materials. Make round parts with excellent finish without clamping marks by reducing initial clamping forces.

No more compromises

Follow instructions from your cutting tool provider without choosing between clamping force and RPM.

Choose spindle speed without safety concerns. Rindex Counterweights make sure that your parts stay in place, even when using large, heavy jaws far out on the chuck.

New cutting tool technology allows for even faster spindle speeds without having to change tools as oftan due to wear out. As long as the cost of tools and time for tool change is less than that of increased machining time, you should increase spindle speed accordingly.

Spindle speed is inversely proportional to time when you set the feed rate in a per-revolution fashion. If you can double spindle speed, the cycle time will be cut in half.

This effects finish turned operations as spindle speed is limited at low clamping forces due to the centrifugal forces caused by the jaws.

Focus on your business objectives

Maximize business value by optimizing cutting data through spindle speed.

Focus on:

- Low production cost – Higher profits

- High quality output – Customer satisfaction

- Maximal output – shorter delivery time

Optimization made easy

Most parts require several operations using different cutting tools, each associated with an optimal clamping force and spindle speed.

Rindex Counterweights allowes you to adjust the clamping force by adding and removing extra weights. The optimal clamping force curve can be used for each tool, meaning consistently high-quality output without adjusting the initial clamping force.

Read our success stories and learn more about how it is done here.

Become #1 supplier

Take on more jobs and difficult tasks. Efficiency allows for less machine downtime and increased capacity. Reach out to more customers and expand your business reach.

Inspection and error correction of work in progress take up to 50% of internal setup time. More consistent processes mean fewer errors and less time spent on setup.

The Rindex System allows for kN/RPM settings for different tools and operations to be standardized and easily handed out to machinists, who may have different levels of knowledge and experience. Those machinists then don’t have to worry about making mistakes in setup that will result in lost time and productivity.

New cutting tool technology reduces the clamping force needed for several operations. By combining:

- the best cutting tools for the job, with…

- Rindex Multi-Jaws, providing 100 % clamping surface,…

- using a higher friction jaw material, such as aluminum, and …

- Rindex counterweights, …

you can approach zero clamping force, with the highest possible quality as a result. Do not forget to wash your raw material clean for the best result!

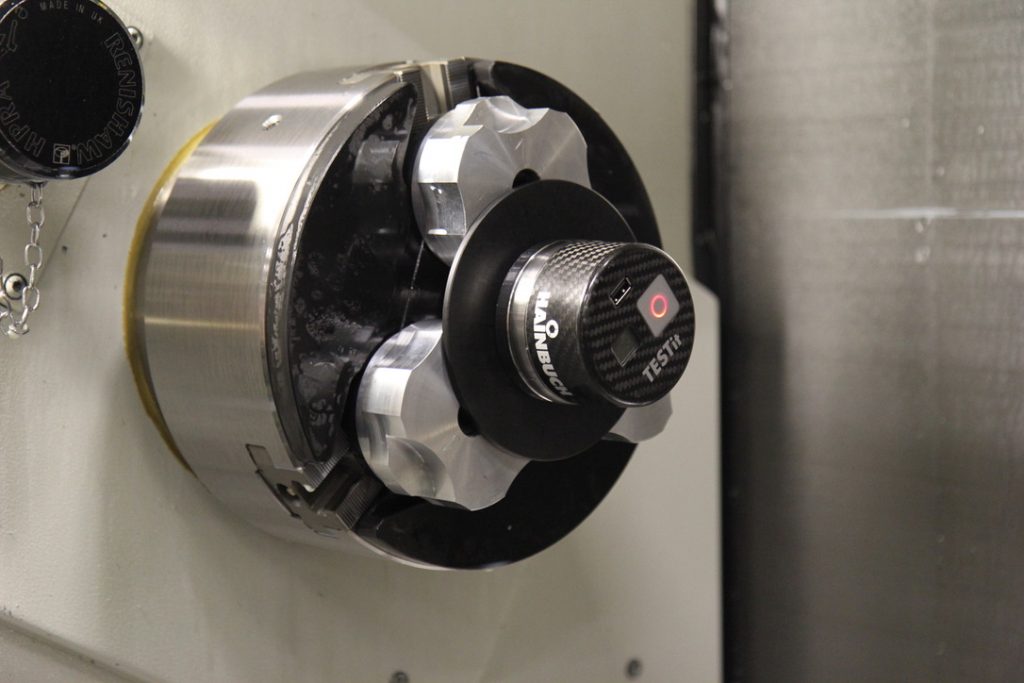

Set and forget

Counterweights can be attached to your primary or secondary spindle.

No set-up cost

Quick set-up, or detachment, with special set up tool.

Low maintenence

Our counterweights seal the chuck surface, resulting in much less chuck maintenance.

- Shorter delivery time

- Partial delivery

- No clamping marks

- Superior surface finish

cutting tool technology enableing high speed machining

The tradeoff between metal removal rate (MRR) and cutting tool life is no more. Because of recommendations from cutting tool providers, manufacturers have been careful using the machines full capacity due to shorter cutting tool life. The reason is simple – inserts cost money and, (much) more importantly, it takes time to change them.

However, If the increase in parts per minute is larger than the loss of operator time and insert cost, you should increase MMR when possible.

The latest cutting tool thechnology allowes for quicker change over time, prolonged tool life, more efficient cooling technology and higher cutting speeds.

As the latest cutting tools (quick change, long lasting, coolant efficient) allow for higher speeds (RPM), they make the analysis easy for us.

(The counterweights have the largest potential when jaws affect centrifugal force so that potential speed increase can not be reached due to loss of clamping force limit)

An example:

Tools

Arno-Werkzeuge USA LLC:Cut tool change time from 7 to 1 minute (read here)

Sandvik Coromant: Increase insert tool life by 50-200% (average 100%), compared tocompetition (read study here)

MPC Automation Systems: Increase RPM by 50 – 200 % (average 100%)

Operations

Machine cost an hour: $ 80 per hour, $ 1,33 per minute

Swaps per day: 6

Conventional turning

7 minutes * 6 swaps * $ 1,33 = $ 56

Using quick change inserts

1 minute * 6 swaps * $ 1,33 = $ 8

Using long lasting inserts (without quick change)

7 minutes * 6 swaps* 0,5 (100% increase in tool life) * $ 1,33 = $ 28

Using long lasting inserts (with quick change)

1 minutes * 6 swaps * 0,5 (100% increase in tool life) * $ 1,33 = $ 4

With counterweights (MRR), (without long lasting inserts)

1 minute * 6 swaps* 0,5 (100 increase in MRR) * $ 1,33 = $ 4

With counterweights (MRR), (with long lasting inserts)

1 minute * 6 swaps* 0,5 (100% increase in tool life) * 0,5 (100 increase in MRR) * $ 1,33 = $ 2

Findings: If you use quick change inserts and use the extra tool life provided by, for example, Sandvik Coromants cutting tools, you should be able to increase Metal removal rate alot by increasing RPM.

New “quick change” cutting inserts reduces change over time from 5 minutes to under a minute, according to Arno-Werkzeuge USA LLC.

The latest cutting tool inserts and cooling technology can increase tool life with up to 200%, according to Sandvik Coromant.

Whils most of the quotations below refere to milling, it is safe to assume that it is true for CNC lathes as well. Source: CNC Cookbook

Choosing tools, feed rate, cut depth and spindle speed is the most difficult task that a machinist does on a daily basis, according to a survey conducted by CNC Cookbook. There are simply too many variables to take into account.

About 25 % of operators choose speeds and feeds after “standard cuts”, “rule of thumb” or by “sound and feel”. Needless to say, this approach will not result in optimal metal removal rate.

Whilst there are many software applications that will provide you with a rough estimate, most of them are simplistic and/ or outdated and do not take your company’s overall objective into account, i.e., high gross profit, best surface finish, lowest possible cycle time, long tool life etc.

For instance, tool providers often recommend cutting data that increases tool life with little respect to metal removal rate. New “quick change” cutting tool technology reduces change over time from 5 minutes to under a minute, according to SECO. In addition, the latest cutting tool inserts and cooling technology can increase tool life with up to 200%, according to Sandvik Coromant.

Conclusion

Use more advanced software when calculating speeds and feeds, take overall business objectives into account, choose tools, and inserts wisely and increase MRR to reduce cycle time as often as possible.

lathe Speeds And Feeds

Every company is unique

Find out how your company can improve efficiency by looking general data from the manufacturing industry, such as overhead costs, time spent on different operations, key economic indicators (component cost, gross margin) etc.

Calculate your profits

Every company is unique

The following examples are built on assumptions. Find out how your company could benifit from Rindex by clicking “Calculate profits” or by clicking “Succes Stories” under “Why Rindex” in the top menu.

Read more…

Normal Output = 50 pieces an hour (32% in cirkle diagram to the left).

By cutting rework (21%), inspection (8%) and jaw change time (13%) you can produce an extra 65 pieces an hour. That is an increase by 131% to a total of 115 pieces.

When turning 2 times faster = 115 * 2= 230 pieces can be made.

That increases the number of parts per minute with 360%. According to sandviks calculations, that equals a gross margin increase with 180%, or…

A decrease in component cost by 78%.

Decrease component cost with up to 85+ %,

By … Increasing spindle speed with up to 3 times,

Cutting rework-, inspection and jaw change time.

Resulting in … 300% increase gross margin.

https://www.sandvik.coromant.com/sv-se/services/manufacturing/pages/default.aspx

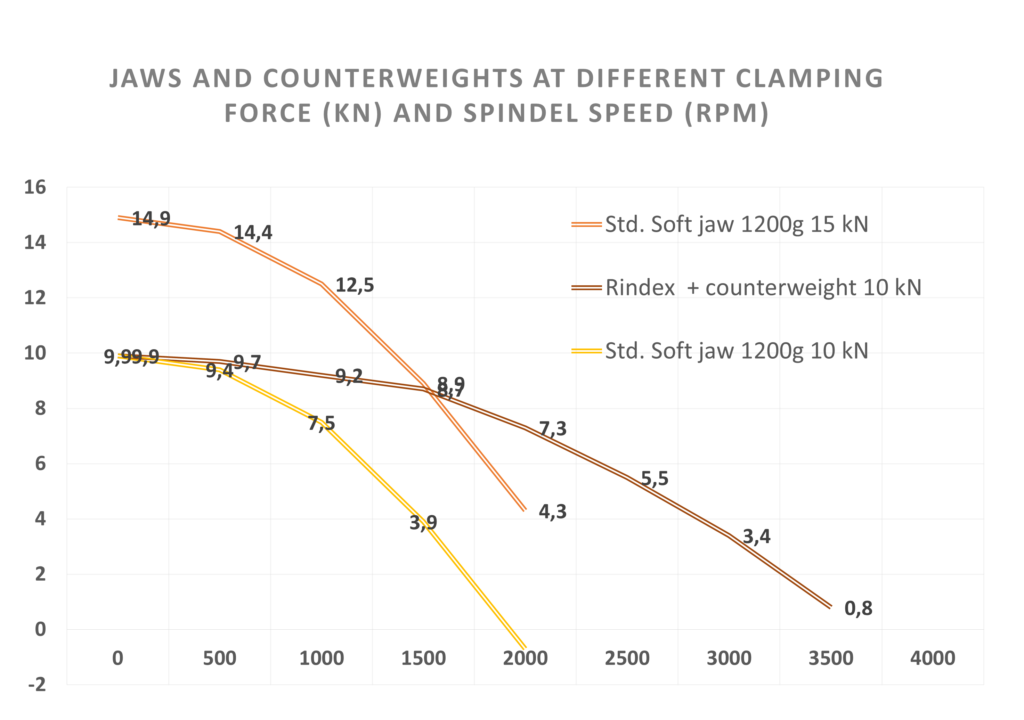

Thin walled and/or sensitive parts need low initial clamping force.

Size, weight and location of jaws will greatly reduce clamping forces as spindle speed (RPM) increase.

Increased machine operation time and metal removal rate will have huge impact on overall costs.

Trade Of:

Clamping Force (KN) VS: Spindle Speed (RPM)

When clamping force is set to 10 kN, the maximal spindle speed is about 1000 RPM.

This effects number of parts/ minute, surface structure and cutting tool life.

You will not be able to follow recomendations from your cutting tool provider.

When using an 8 hour shift, machine operating time is equal to about 2 hours.

By increasing spindle speed, you will be able to produce more in those 2 hours.

Spreed up, for fast returns

Counterweights can increase metal removal rate by a factor of 3, or 200%, when applicable.

A 200% metal removal rate increase equals a 70% lower component cost and a 3 times increase in gross margin.

By producing high quality parts without clamping marks and deformations, you can:

- Reduce rework

- Reduce Measurement time

- Eliminate waste and thus…

- Order less raw materials to keep in stock.

Your machine time is extreamly valuable. So is your customer relations as well as your ability to bring in new business.

By increasing productivity (turn faster) and quality (soft clamping), you will be able to take on more customers.

Every company is unique

The value that our counterweights will bring to your business depends on your type of manufacturing. The more you are willing to change your manufacturing today, the more money you will make down the line.

If you are making simple parts, use our simple counterweghts and simply turn faster with less clamping force. Since they are easy to set up and use there is no need to invest much time with experimenting with optimal RPM and Clamping forces.

However, if you make more difficult and time consuming parts, where several operations needed, you want to optimize production. Especially if you have repeting jobs. Then, by experimenting with extra weights, you can find a “sweet spot” where your cutting tools perform at top with right clamping force and RPM.

By investing in future technology early, you are ahead of your competition.

Make your own calculation

With Rindex system mounted on several machines where jaw changes are more frequent, you get exponential returns. Make your own calculations on our website here.

Success Stories

” Parts were manufactured 2-3 times faster compared with traditional turning. This means we managed to increase gross margin by 100-150 % as well as lower the component cost with 50- 80%, just by turning faster”

Joel Jönsson, MPC Automation Systems, Success Stories, LK Precision, 2022.

With our new product line, there are many ways to success. Read about how and why the Rindex system is a prize winnig product.

Get inspired by others

Find out how other manufacturers use mpc's products to enhence productivity and profits.

Rindex works for you

Calculate profits

Here is how much money your unique company can save by using our products.

Optimization made easy

Learn how to optimize cutting data by choosing correct clamping force and spindle speed.